What are micro encapsulated lipid powders and why use them?

Encapsulating a nutrient, such as a vitamin or supplement, within a lipid provides enhanced protection from environmental, chemical, and physiological damage.

Nutrients such as Omega 3 DHA, CoQ10, Astaxanthin, Curcumin, Glutathione, Antioxidants and Polyphenols are highly susceptible to environmental degradation; this can occur through oxidation, high temperatures, and reaction with other compounds.[I]

Lipid encapsulation stabilizes a nutrient’s volatility and bolsters its bioavailability; the nutrient becomes ‘anti-fragile’. (to a degree).

Upon ingestion, the lipid encapsulated nutrient is shielded from being destroyed through digestion and is more easily delivered to target areas of the body. Critically, liposomes’ structure resembles that of human cell membranes, and therefore, are seamlessly absorbed into the body’s cellular matrix, delivering nutrients directly into the cells.

If liquid lipid emulsions are so effective at improving bioavailability, why go to effort of microencapsulating spray drying them?

Spray drying is the most suitable method for the microencapsulation of polyphenols.[ii]

What does micro-encapsulating liposomal and micelle powders entail?

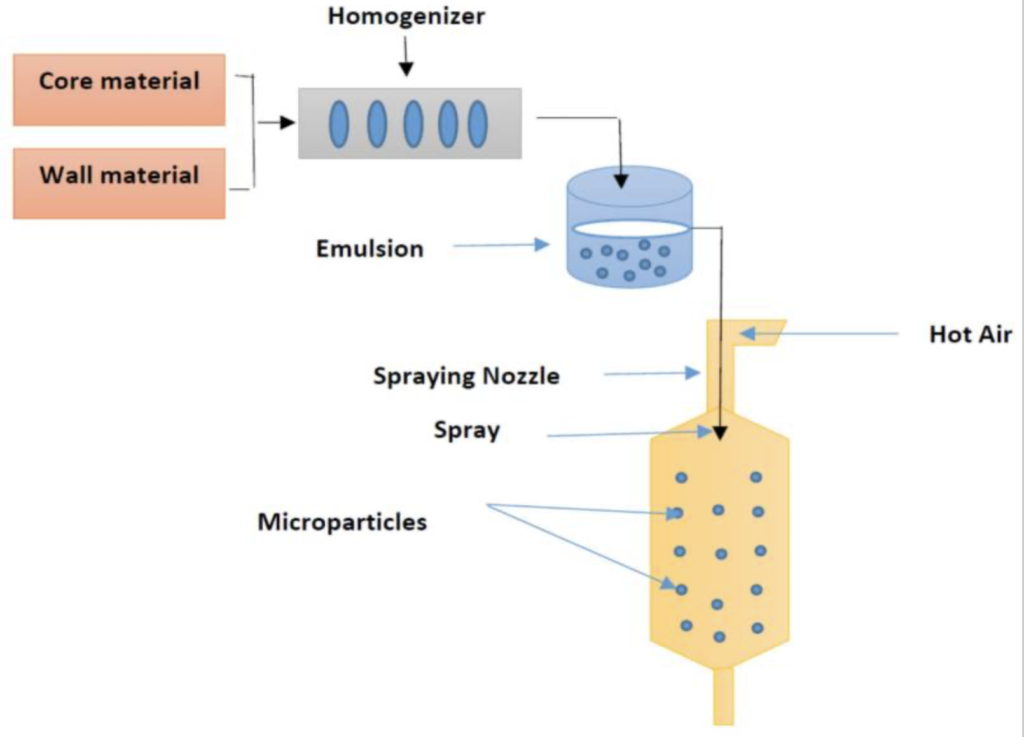

The micro encapsulated spray drying process involves the following steps:

- Formulation: We combine the active ingredients: the core nutrient, a phospholipid containing fat (‘the wall material’), and cyclodextrin (a low glycemic carbohydrate). See figure 1.

- Dissolution: The formulation is dissolved in a liquid carrier.

- Atomization: The emulsified supplement is then pumped into a spray dryer. We use a rotary atomizer to disperse the liquid into tiny droplets, to increase the surface area exposed to warm air.

- Drying to evaporate the water from the emulsion. At Virun, we are careful to only use low temperatures in a vacuum chamber to avoid compromising the integrity of the liposomes.

- Particle Collection & Cooling: The particles are collected and gently cooled in a chamber to prevent moisture absorption and ensure stability.

Spray drying emulsifications can deliver many added benefits to the supplement, including:

· Increasing a formula’s stability and shelf life, especially for polyphenols and environmentally volatile nutrients.

· Neutralizing the smell and taste so that a formula’s flavor remains intact, ideal for creating the flavors you desire, or creating unflavored, unsweetened supplements for customers who want no additives.

· Standardizing the mouthfeel and consistency across nutrients.

· The phospholipids which constitute the ‘wall material’ increase the absorption of the nutrients, improving overall bioavailability and efficacy.

· The polysaccharide cyclodextrin—which we use at Virun—is proven to increase nutrient absorption and further stabilize nutrients’ smell and taste while consolidating shelf life and bioavailability.

· Spray dried lipid powder nutrients allow for more innovative formulas as they can be combined with other powdered nutrients that do not need to be lipid encapsulated, so that you can create a formula which includes both fast release and slower release nutrients. For example, you could blend lipid encapsulated DHA Omega 3 powder with a non-encapsulated collagen powder or protein powder.

Why do we use Cyclodextrin?

The polysaccharide cyclodextrin is a tasteless, noncaloric dietary fiber produced by enzymatic degradation of starch. We use it in powdered formulations as it increases nutrient solubility in aqueous solutions and helps to convert oils and liquid nutrients into microcrystalline powders. Furthermore, they impart other benefits such as reducing gastrointestinal irritation[iii]; they stabilize stabilizers of dietary lipids, such as unsaturated fatty acids, phytosterols, vitamins, flavonoids, carotenoids and other nutraceuticals.

Cyclodextrin has a low glycemic index (GI) and lowers the GI of foods consumed alongside it. It is renowned as an anti-obesity, anti-diabetic[iv] carbohydrate, favored by body builders for maintaining muscle mass while cutting fat.

Cyclodextrin based lipid technology has even been found to improve the ‘therapeutic effect and sustain long life of healthy and recovered (cancer) cells.’[v] Another study (on horses) demonstrated increased skeletal muscle growth with daily supplementation of CoQ10 and cyclodextrin.[vi]

Spray drying allows you to create a muti-nutrient blend with both fast and slow-release nutrients, compounded with phospholipids to increase absorption and protect those sensitive molecules, giving your formula multi-dimensional applications.

Which supplements need the additional microencapsulated lipid powder protection?

- Antioxidants

- Polyphenols

- Curcumin

- Omega 3 DHA: Discover our patented algae DHA lipid powder.

- CoQ10

- Astaxanthin

- Curcumin

- Glutathione

One study in the Journal of Morphological and Molecular Mechanisms demonstrated how micro-encapsulated spray dry powder increased the bioavailability and efficacy of Curcumin to reduce inflammation, optimize cognitive function, support cardiovascular health, and stabilize blood sugar levels amongst participants.[vii]

What to be aware of when planning a micro-encapsulated spray dry powder, liposomal powder or micelle powder?

Many manufactures use a high heat spray drying technique. This certainly speeds up the time it takes to produce the supplement BUT high temperatures often denature and degrade nutrients, leaving you with expensive and redundant powders.

Be careful of the carbohydrates used, some spike blood sugar levels and others cause gastrointestinal distress. Maltodextrin is a commonly used culprit in spray dry powders.

Powder microencapsulation is not ideal temperature sensitive bioactive substances[viii]. Some oils are sensitive to environmental factors such as heat, oxygen, metal ions, and humidity. Thus, these oils are microencapsulated by different methods. High temperatures adversely affect the structure of phenolic compounds, causing structural breakage, resulting in the formation of different compounds, thereby reducing the antioxidant activity[ix]. This is why, at VIRUN, we use low temperatures to slowly, gently spray dry lipid encapsulations in a vacuum to further protect the nutrients.

Why risk compromising on the efficacy of your supplement line?

Speak to us today to upgrade your formulas innovate.today@virun.com

Explore our patents here and discover our patented bicarbonate downstream process which allows us to naturally preserve volatile nutrients, without compromising the efficacy.

REFERENCES

[i] “Encapsulation of oils improves the oxidative stability of their lipids and protects sensitive constituents (core) such as active compounds, oils, flavour compounds, and vitamins from environmental factors.” Mohammed NK, Tan CP, Manap YA, Muhialdin BJ, Hussin ASM. Spray Drying for the Encapsulation of Oils-A Review. Molecules. 2020 Aug 26;25(17):3873. doi: 10.3390/molecules25173873. PMID: 32858785; PMCID: PMC7503953.

[ii] Fang Z, Bhandari B. Comparing the efficiency of protein and maltodextrin on spray drying of bayberry juice. Food Res Int. 2012;48:478–483. doi: 10.1016/j.foodres.2012.05.025.

[iii] Diomede F, Fonticoli L, Guarnieri S, Della Rocca Y, Rajan TS, Fontana A, Trubiani O, Marconi GD, Pizzicannella J. The Effect of Liposomal Curcumin as an Anti-Inflammatory Strategy on Lipopolysaccharide e from Porphyromonas gingivalis Treated Endothelial Committed Neural Crest Derived Stem Cells: Morphological and Molecular Mechanisms. Int J Mol Sci. 2021 Jul 14;22(14):7534. doi: 10.3390/ijms22147534. PMID: 34299157; PMCID: PMC8305631.

[iv] https://www.ema.europa.eu/en/documents/scientific-guideline/questions-and-answers-cyclodextrins-used-excipients-medicinal-products-human-use_en.pdf Europeean Medicine’s Ageny ‘Cyclodextrins used as excipients’

[v] Fenyvesi É, Vikmon M, Szente L. Cyclodextrins in Food Technology and Human Nutrition: Benefits and Limitations. Crit Rev Food Sci Nutr. 2016 Sep 9;56(12):1981-2004. doi: 10.1080/10408398.2013.809513. PMID: 25764389.

[vi] ‘Cyclodextrin-based nanotechnology seems to provide better therapeutic effect and sustain long life of healthy and recovered cells’ Gidwani B, Vyas A. A Comprehensive Review on Cyclodextrin-Based Carriers for Delivery of Chemotherapeutic Cytotoxic Anticancer Drugs. Biomed Res Int. 2015;2015:198268. doi: 10.1155/2015/198268. Epub 2015 Oct 25. PMID: 26582104; PMCID: PMC4637021.

[vii] Rooney, M.F., Curley, C.E., Sweeney, J., Griffin, M.E., Porter, R.K., Hill, E.W., & Katz, L.M. (2020). Prolonged oral coenzyme Q10-β-cyclodextrin supplementation increases skeletal muscle complex I+III activity in young Thoroughbreds. Journal of Applied Animal Nutrition, 8(1), 11-20. https://doi.org/10.3920/JAAN2019.0001

[viii] Demeng Zhang, Mengxue Zhang, Xiaoxiao Gu, 8 – Seaweed-Derived Hydrocolloids as Food Coating and Encapsulation Agents, Editor(s): Yimin Qin,Bioactive Seaweeds for Food Applications, Academic Press, 2018, Pages 153-175, ISBN 9780128133125, https://doi.org/10.1016/B978-0-12-813312-5.00008-X

[ix] Mishra A, Sharma AM, Kumar S, Saxena AK, Pandey AK (2013) Bauhinia variegata leaf extracts exhibit considerable antibacterial, antioxidant, and anticancer activities. BioMed Res Int. doi:10.1155/2013/915436